#1 Residential & Commercial

Fertigation Injection Systems

We could show you one of our patented, unparalleled and highly advanced fertigation systems here… But, we decided to show you what you really get when using an EZ-FLO system…

Health, lush and beautiful landscapes, flowers, trees and lawns. You can thank us later.

Available at these leading retailers

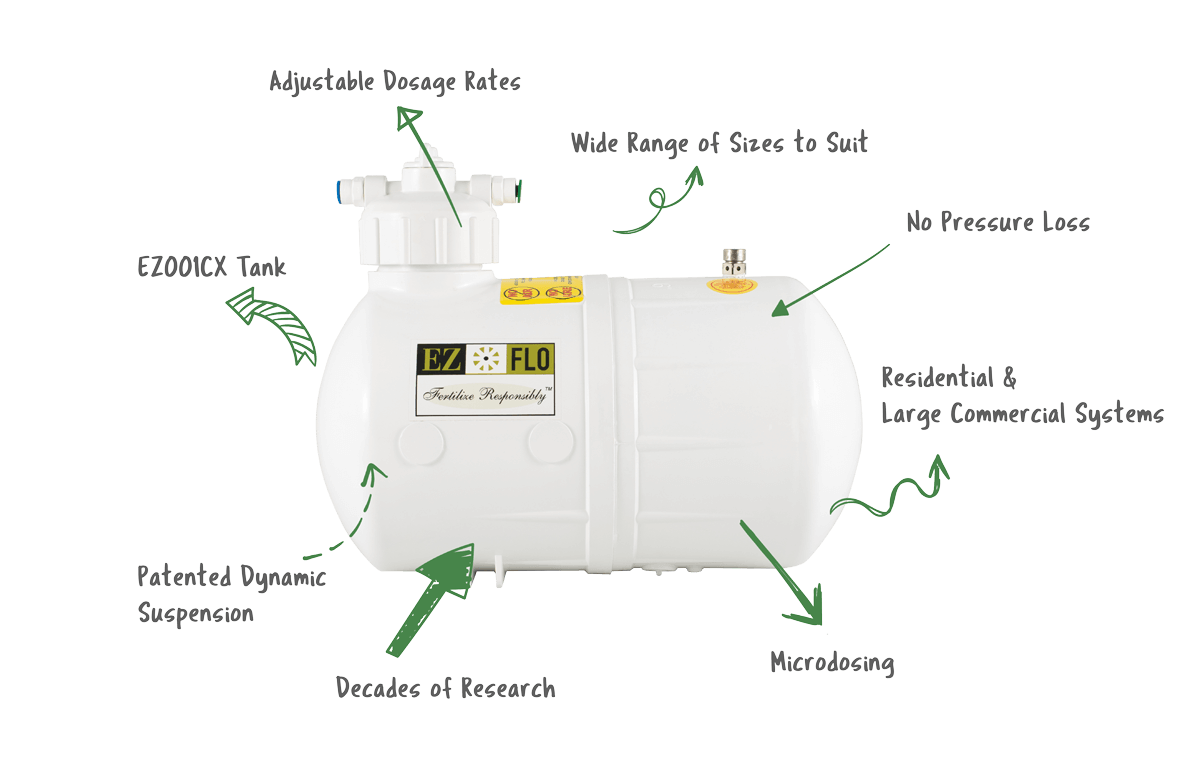

Big Features. Bigger Benefits

The first rule of EZ-FLO: Anything that grows, just looks better! EZ-FLO is a simple system. It doesn’t need power. It needs very little maintenance. Let’s take a basic look at how it works below.

Why Choose EZ-FLO?

EZ-FLO let’s you release an exact amount of nutrients into the soil, no matter the soil or landscape conditions. Since the fertilizer is in the actual water, nutrition travels further and deeper, and reaches more of the roots. The more the roots absorb, the better your landscape looks.

best seller

Meet our 1.5 Gallon Injection System

There’s a reason this is our best selling residential system. It’s the perfect size for most small home gardens and lawns.

Healthier Lawns

Healthier Flowers & Trees

Tasty Herbs

1000s of Customers Love Their EZ-FLO

What does EZ-FLO do?

At EZ-FLO, we do fertigation. That’s fertilization, but better in so many ways.

EZ-FLO specializes in two things:

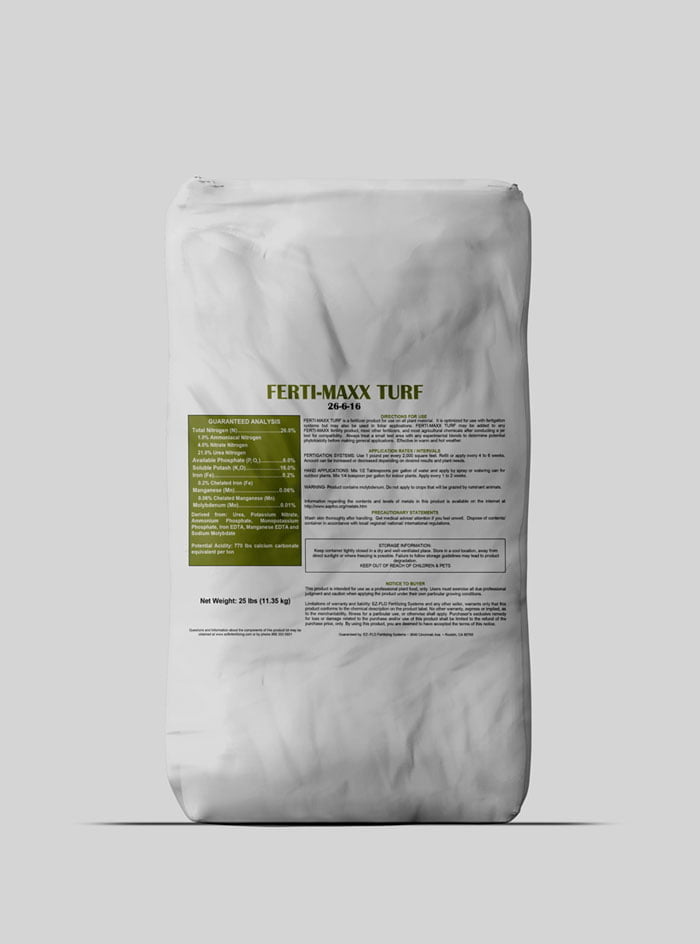

Consumables

We have fertilizers, water treatments, and repellents. All developed to be safer, smarter, and more eco-friendly than the average brand.

Hardware

Our intuitive fertigation systems deliver liquid fertilizers directly to the roots. They’re low-maintenance so you can forget about them. Easy to set up so they’re frustration-free. And work automatically so you work less!

Fertigation Systems

At EZ-FLO, there’s a range of dispensing systems to suit whatever you’re planting, and the size of your space. Be it lawn grass, flowers and vegetables from your garden, or agricultural crops on your farm.

Not sure what you need? That’s why we’re here! Talk to us about what you’re growing, where you’re growing them, and how big the land is. We’ll know exactly what you need to make your plants grow bigger, better, and faster - no second guessing!

PERFECT FOR HOME LAWNS & GARDENs

View Our Residential Range

Super quick to set up and super simple to use. EZ-FLO’s Hose and Drip systems connect directly to your outdoors water faucet. The fertilizer or any water soluble product goes through the tubes to join up with your water source. Now you’re fertigating like a pro directly from your garden hose!

Healthier Lawns

Healthier Flowers & Trees

Tasty Vegetables

Consumables

EZ-FLO dispensing systems work with any kind of liquid you choose to feed your plants. However, we make it a point to make your life easy by providing anything and everything you might need, right here.

Shop our comprehensive line of liquid and water soluble fertilizers, fertilizer supplements, water treatments, and pest repellents.

All consumables are designed and developed with the EZ-FLO dispensing systems in mind. This means that together, they use less fertilizer, less water, and spread nutrients faster, further, and deeper into the soil.

FARMS, NURSERIES, SPORTING FIELDS, GOLF CLUBS & MORE

View Our Mainline Range

Got an area you need to fertigate that’s up to 20+ acres in size? One of our Mainline models is what you’re looking for. EZ-FLO’s Main Line systems attach to your irrigation system so fertigation is automatic and convenient.

Reduce Water

Save Man-Hours

Improve Quality

Irrigation Chemistry

When you fertigate with EZ-FLO, you’re combining fertilizers with water. This gives your plants a healthy, well-mixed, nutrient boost that can be injected directly into the soil. The nutrients are dispersed evenly within the water, and the dispensing system does the rest.

What you end up with is a patch of greenery where every plant has been fed fair and square. That’s the consistency you need to produce the most uniform, lush, crisp lawns, vegetable plots, and flower beds. Absolutely gorgeous!

View Our Fertilizers & Treatments

View Our Fertilizers & Treatments

There’s a reason this is our best selling residential system. It’s the perfect size for most small home gardens and lawns.

Healthier Lawns

Healthier Flowers & Trees

Tasty Herbs

Ditch the Dry Stuff

With normal fertilization, or broadcast fertilization, you’re spreading dry or granular fertilizer on top of your plants and grass. Dry fertilizer isn’t absorbed until it gets wet. You’ll have to wait for it to rain, manually water the fertilized area with a watering can or hose, or get the sprinklers going. Even then, it takes time and enough water for the fertilizer granules to dissolve.

This means you’ll get an inconsistent amount of nutrition seeping into the soil at uncertain times. Your plants will have a harder time absorbing its nutrients. Some will have more food, others will have less.

Using dry fertilizer results in:

- A lot of physical labor

- An uneven spread of fertilizer

- An inefficient use of fertilizer that’s hard for your plants to absorb

Why spread fertilizers by hand, lug a broadcast spreader around, or go through the hassle of trying to remember when you’re supposed to be fertilizing?

Boring, back-breaking, manual fertilization is a thing of the past when you can grab an EZ-FLO system, fill it up, then set it and forget it!

Want healthier landscapes and plants?

Find one of our trusted irrigation specialists near you. Purchase online and in store with your preferred retailer.